UNS S4500 Bar

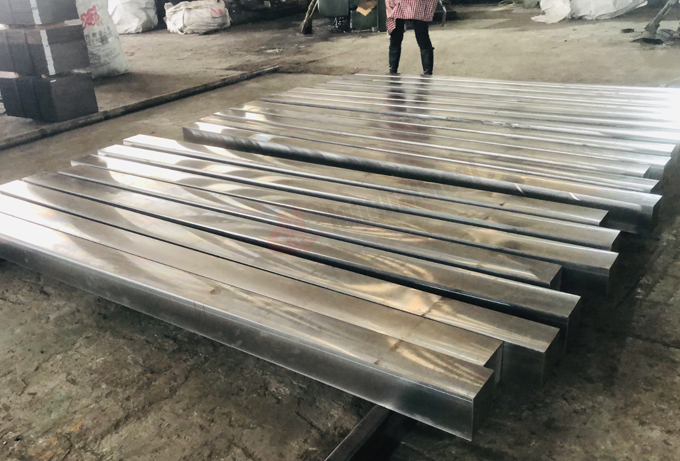

Flat steel for making blades.

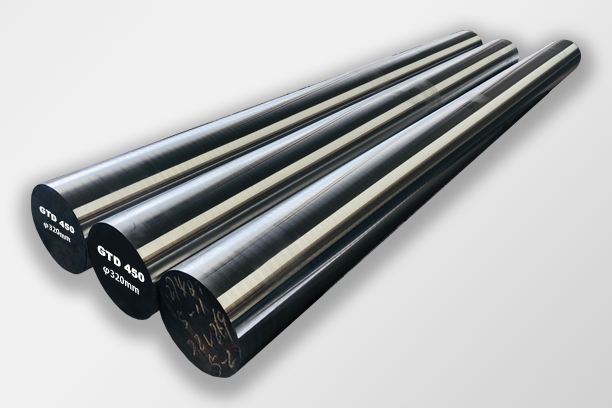

Round Bar: Dia.8mm to Dia.600mm

UNS S45000 stainless has very good corrosion resistance with moderate strength. A single-step aging treatment develops higher strength with good ductility and toughness. A martinsitic precipitation hardening steel, UNS S45000 stainless steel offers high strength combined with excellent corrosion resistance similar to 304 stainless in corrosion resistance with moderate strength similar to that of 410 stainless. As with most precipitation hardened alloys, UNS S45000 stainless has excellent transverse properties. Used when ease of welding and brazing in fabrication is required. UNS S45000 unlike many precipitation hardening grades, UNS S45000 can be used in the annealed condition. Applications: Valve parts, Paper mills, aircraft and power generation, chemical processing, nuclear and space craft.

UNS S45000 is a type of precipitation-hardening stainless steel that is also known as Alloy 450 or Custom 450. It is a martensitic steel that is strengthened through the precipitation of copper and niobium carbides during a heat treatment process.UNS S45000 is characterized by its high strength, good corrosion resistance, and excellent toughness. It is often used in applications that require a combination of these properties, such as aerospace components, medical implants, and marine equipment.In terms of its composition, UNS S45000 contains significant amounts of chromium, nickel, and molybdenum, which provide its corrosion resistance properties. It also contains small amounts of copper and niobium, which help to form the precipitates that give the steel its strength.The heat treatment process used to strengthen UNS S45000 involves solution annealing at high temperatures followed by rapid cooling, and then aging at a lower temperature to form the precipitates. This process allows the steel to achieve high levels of strength while maintaining its toughness and ductility. Overall, UNS S45000 is a high-performance stainless steel that is well-suited for applications that require high strength, good corrosion resistance, and excellent toughness. Its unique combination of properties makes it a popular choice for a variety of demanding applications in industries such as aerospace, medical, and marine.

Flat steel for making blades.

Round Bar: Dia.8mm to Dia.600mm

Flat steel for making blades.

Flat Bar: width 30mm to 800 mm, Thk. 30mm to 500 mm

Finished blade

| Element | WT % |

|---|---|

| C | max 0.05 |

| Mn | max 1.00 |

| Si | max 1.00 |

| P | max 0.03 |

| S | max 0.03 |

| Cr | 14.00-16.00 |

| Cu | 1.25-1.75 |

| Ni | 5.00-7.00 |

| Mo | 0.50-1.00 |

| Nb | min 8 x (%C) |

| Properties | Metric | Imperial |

|---|---|---|

| Thermal expansion co-efficient ( @ 20-100°C/68-212°F) | 10.1 µm/m°C | 5.61 µin/in°F |

| Thermal conductivity (typical value for stainless steel) | 20.7 W/mK | 144 BTU in/hr.ft².°F |

UNS S4500 stainless steel alloy uses feeds and speeds comparable with other martensitic stainless steels. It is preferred to use positive feeds and slow speeds to achieve good results.

UNS S4500 stainless steel alloy can be welded using shielded methods to reduce contamination.

UNS S4500 stainless steel alloy can be hot worked by soaking at 1150-1177°C (2100-2150°F) followed by cooling and fully annealing.

UNS S4500 stainless steel alloy can be cold worked using all common techniques.

UNS S4500 stainless steel alloy is annealed by soaking at 1024-1052°C (1875-7925°F) for 1 h followed by quenching in water or oil.

UNS S4500 Grade 450 stainless steel alloy is soaked at specific temperature for 4 h followed by cooling to obtain condition H900, H950, H1000, H1050 or H1150.